At A-Consult, we offer a wide range of tank solutions along with fast and professional installation. Contact us today to have your new tank installed efficiently and seamlessly.

Industrial

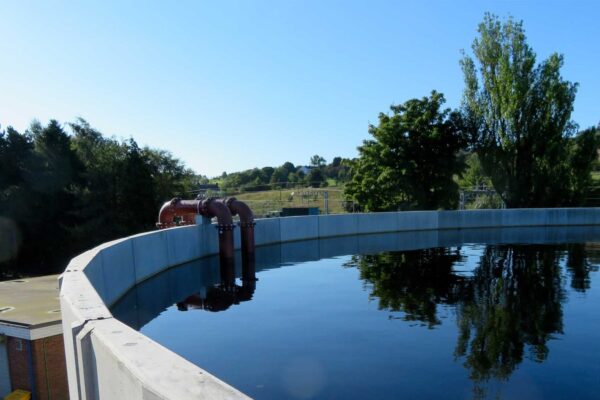

Durable concrete tanks for industrial applications

A-Consult’s proven expertise in concrete containment solutions is built on decades of experience and the flexible AQUA-TANK system, which utilizes standardized and tested construction methods.

We collaborate closely with clients and consultants from the early planning stages, offering expert guidance to optimize both quality and cost efficiency.

Depending on project requirements, we operate as a specialist, main, or turnkey contractor—always committed to delivering the best value and long-term reliability for our clients.

When you choose an Aqua-Tank from A-Consult, you benefit from:

Hidden Strength

The AQUA-TANK is constructed using high specification concrete panels held together by a series of circumferential 7 wire PE-sheeted grease impregnated tendons.

The tendon is coated in a highly corrosion-resistant grease conforming to the recommendations of both the American Post Tensioning Institute and the FIB.

The PE-sheeting is formed by the continuous hot extrusion of high density polyethylene or polypropylene to a minimum

redial thickness of between 1.00mm and 2.00mm, again conforming to recommendations of both the America Post Tensioning Institute and the FIB.

Panel to Base Seal

The panel to base seal is typically performed by applying a rebate solution to the base slab. The A-Consult panels can be provided with dowel bars if required. Below shows a typical ring beam section showing how an effective seal is achieved by utilizing the step in the base slab along with the correct placement of three strips of hydrotite.

Additional security can be achieved during the construction of the in-situ ring beam by forming a small rebate to the inside face and then by filling this rebate with a elastic polyurenthane sealant after the ring beam has cured.

Panel Seal

The AQUA-TANK panel seal is unique due to the use of a patented, WRAS approved, substantial EPDM Rubber strip, which absorbs the movement to which every tank is subjected; e.g. seasonal weather changes, variation in liquid level and external pressure from back-fill.

Its elasticity is resistant to ammonia and ultra violet light, and with a life expectancy in excess of the concrete panels themselves results in no maintenance on this area for the structures total design life.

AQUA-TANK provides a safe, cost effective method of containment with numerous applications within the Water, Waste and Industrial sectors.

Guaranteed factory controlled quality combined with a robust structure along with tried and tested design principals, offer life expectancy previously only achieved with cast in-situ installations.

A-Consult are the market leaders in the Design, Manufacture and Installation of Precast Concrete Storage Tanks.

We can also utilize other recognized design patterns. Through close collaboration with our clients and their consultants, we can fully optimize the potential of A-Consult’s precast concrete tanks. Pre-cast holes in the concrete slabs facilitate pipe installations or the fitting of complex decanting systems, as well as mixer inlets and access hatches. The casting of anchor points and channels enables the attachment of drainage pipes, de-foaming units, cables, external walkways, platforms, and supports for the panels.

The tanks can be fitted with integrated starter beams, which can be cast during production, or separate starter beams that can be secured after installation.

Benefits of AQUA-TANK:

-

Cost-effectiveness – off-site manufacture, fast track installation.

- Rugged construction – resulting in 40-60 years design life

- Guaranteed Quality – manufactured under factory conditions

- Construction programmes reduced – fast track installation carried out in virtually any weather conditions

- Above or belowground installation

- Minimum maintenance

- Optimum storage capabilities – ranging from 50m3 to 12,500 m3

- Kit form construction – allows dismantling and re-siting in the future

- Health and Safety – standardised construction methods

We provide you with the opportunity to alter the appearance of the AQUA-TANK using various types of finishes.

Industrial tank Applications

Process Tank

- Multiple process requirements have been facilitated by using the A-Consult tank system.

- Diverse process applications range from both salt and fresh water fish farms, to Leachate treatment on landfill sites.

- Liners cast into the precast wall units can make the storing and processing of aggressive liquids more reliable.

Leachate Tank

- With a 50 year design life the A-Consult precast concrete tank system offers a cost effective and robust solution to many process and storage applications.

Storage Tank

- A-Consult tanks have been used for the storage of many different materials.

- All materials used in the construction of our tanks are DWI approved allowing the storage of potable water.

Bund Wall

- Bund Wall installed around an Anaerobic Digester supplied by A-Consult.